Injection Molding

Plastic Injection Molding has been the core operation for Artisan Industries, since our founding in 2001. Currently, Artisan operates an all-Milacron injection molding machine fleet, with machine tonnages ranging from 40-400 tons, including multiple Roboshot all-electric machines. As Artisan continues to grow, we are not only investing in state-of-the-art injection molding machinery, but also advanced support and auxiliary equipment, to bolster our operations.

Equipment

- Milacron/Roboshot Injection Molding machines

- Yushin Robotics on injection molding machines

- AEC Mold Temperature Control Units (water and oil)

- Multi-ingredient material blending technologies

- Hot-manifold and valve-gate control systems

- Various support and secondary operations / assembly equipment

Materials

With a 20+ year operational history, Artisan has experience in processing and molding everything from your most common commodity materials, to highly unique custom material compounds. Whatever your job-specific material needs are, Artisan has the experience and expertise to not only confirm you are using the best materials for your application, but also ensure that those materials are processed correctly into a conforming product.

Common Materials Artisan processes (but not limited to):

Polypropylene

Polyethylene

Nylon

ABS

Polyester

Acetal

PPE/PPO

PVDF

Polycarbonate

PBT

PPS

TPE / TPU / MPR / other Elastomers

Ultem

ETP (Isoplast)

Recycled / Reprocessed Materials

Custom Material Compounds

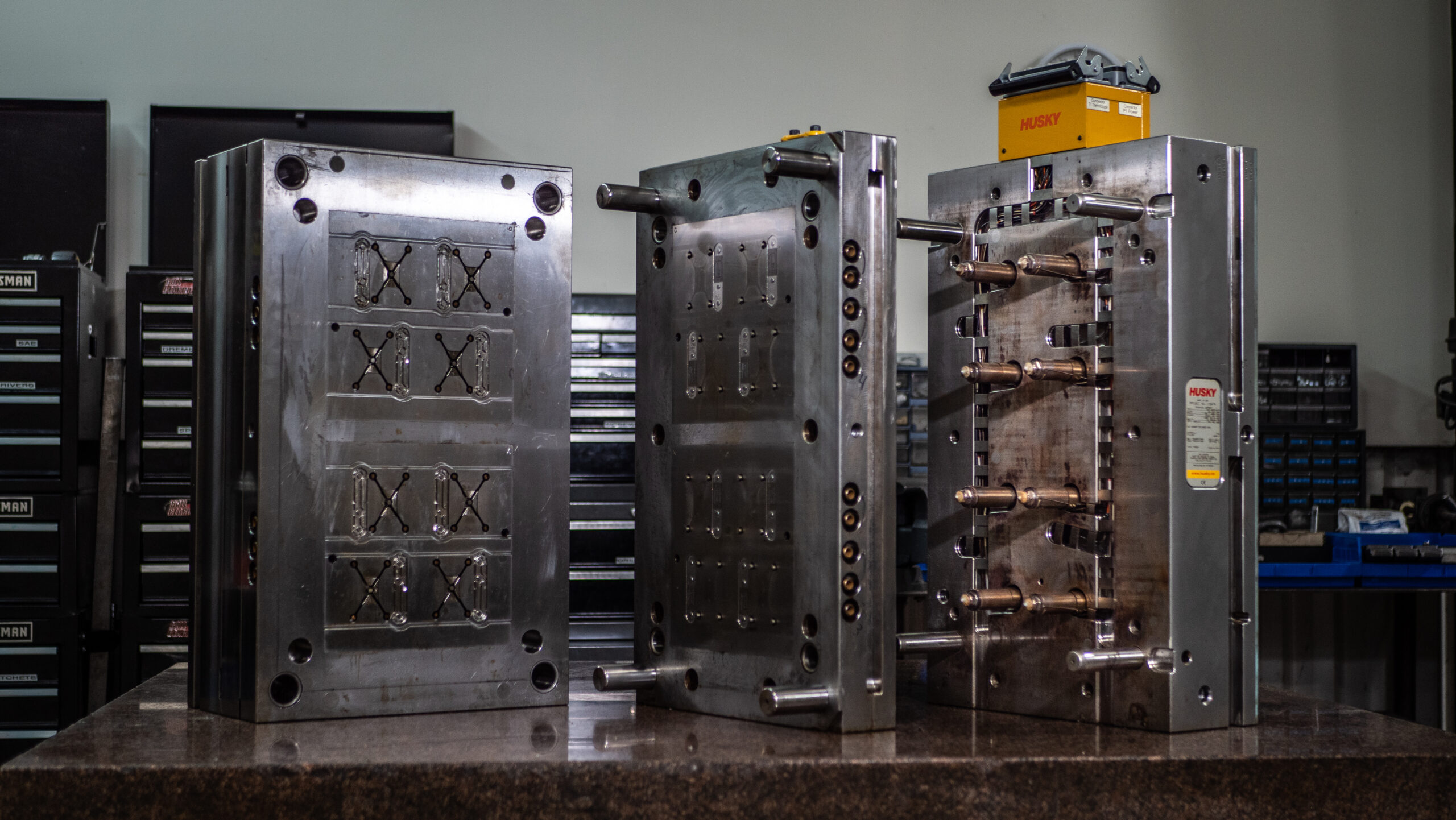

Tooling

Production of quality parts begins with the design and construction of a quality tool. Whether your job requires brand new tooling, or modifications or maintenance to existing tools, Artisan Industries works with a number of toolmakers that specialize in injection molds and other various types of manufacturing/automation fixtures. We have experience with helping design and test a wide range of tools of various complexities, tolerance levels, and life-cycle ranges. Artisan can also determine if your tooling project qualifies for various cost-saving options, such as Master Unit Die (MUD) frames or modular cavity inserts. All tool work can be contracted directly with Artisan Industries; we will ensure that your tooling project is done correctly, on-time, and at a competitive price.